Auxiliary Packaging Line Equipment

Auxiliary Packaging Equipment That Elevates Your Entire Line

Support Systems That Drive Productivity and Precision

Packaging isn’t just about sealing bags or boxing goods—it’s about building a smooth, efficient, and automated production flow. That’s where auxiliary packaging equipment comes in. Our range of support machines is designed to integrate seamlessly with your primary packaging equipment, helping you optimize throughput, reduce manual labor, and maintain consistent quality across every package.

Collection-Accumulation Machines

BMD4 Rotary Collecting Table

BMD4 Rotary Collecting Table

Efficient Finished Product Collection: The curved surface system is designed to gather finished products seamlessly, allowing workers to easily collect and transport them for further processing or packaging.

Versatile Use Cases: Ideal for industries such as food processing, manufacturing, or packaging, where finished products need to be gathered and taken away quickly and efficiently.

Smooth Product Flow: The design of the collection system promotes smooth and continuous product flow, preventing jams and ensuring reliable operation throughout the production cycle.

Adjustable Speed Options: Customizable speed controls for transporting products to ensure that the collection system aligns with production line requirements.

Features

Material: SS-304

Diameter: 1000-1200mm

Height: 750-800mm

Customizable

Rotary Collection-Accumulation Table

Efficient Finished Product Collection: The flat surface system is designed to gather finished products seamlessly, allowing workers to easily collect and transport them for further processing or packaging.

Versatile Use Cases: Ideal for industries such as food processing, manufacturing, or packaging, where finished products need to be gathered and taken away quickly and efficiently.

Smooth Product Flow: The design of the collection system promotes smooth and continuous product flow, preventing jams and ensuring reliable operation throughout the production cycle.

Adjustable Speed Options: Customizable speed controls for transporting products to ensure that the collection system aligns with production line requirements.

Features:

Material: SS-304Diameter: 1000-1200mm

Height: 750-800mm

Variable Speed

Customizable

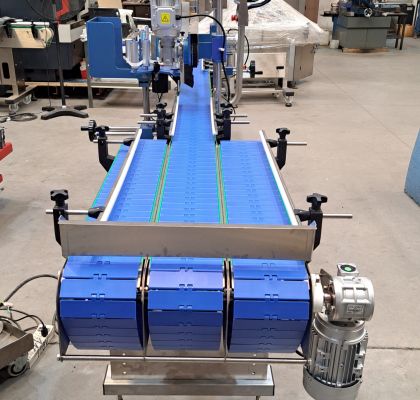

Linear Accumulation Conveyor

Our custom-built Accumulation Conveyors are a safe and efficient alternative to the normal accumulation table that goes at the end of your labeling machine to collect product. They can be made in different lengths to suit your needs. This accumulation conveyor is made of three or more (upon request) chain conveyors.

The main advantages compared to the round tables are:

- Middle conveyor lenght customizable.

- All the products go to the side making it easier for the operator to reach them, in a round table they all go to the center making it harder to reach the products.

- It covers a bigger area of accumulation. With the round tables, there are side rails pushing everything to the center and leaving the perimeter free.

Features:

Material: SS-304Customizable

Conveyors

BMD3 Finished Product Belt Conveyor

BMD3 Finished Product Belt Conveyor

Finished Product Belt Conveyor offers efficient and stable transport for packed goods in your packaging line. This durable Finished Product Conveyor integrates seamlessly with packing machines, ensuring smooth delivery and boosting productivity in industrial operations.

Features

Material: SS-304

Max Speed: 25m/min

Effective Width: 220 or 400mm

Chain Plate Spacing: 250mm

Access Height: 210mm

Discharge Chute Height: 850mm

Customizable Options

Discharge chute height can be increased by 100mm increments

Speed variable frequency adjustable

Inclined Belt Conveyor

The inclined belt conveyor is ideal for efficient packaging lines. As a leading Provider of Inclined Conveyors, including inclined belt conveyors and Inclined Chain Plate Conveyors, it ensures smooth material transport, improves workflow, and boosts productivity in industrial operations.

Features:

Material: SS-304

Effective Width: 300/418/330mm

Spacing between baffles: 250/200/250mm

Conveying System: 25.4/50.8 Pitch chain plate/PU Belt

Access Height: 830mm

Discharge Chute Height: 3100mm

Max Speed: 25m/min

Customizable options

The discharge chute height can be increased by 100mm increments

Speed variable frequency adjustable

Gravity Roller Conveyor

A Gravity Roller Conveyor lets a product move on rollers using the force of gravity to move the load. Gravity conveyors are one of the simplest and most affordable types of material handling systems. They work by allowing the product to roll along the upper surface. When mounted on a slight decline the parts begin moving across the rollers. They are great for warehouses, production facilities, or distribution centers. Most rollers for these conveyor systems are 1.5 inches to 1.9 inches in diameter. For extreme-duty applications, 2.5 inch and 3.5 inch diameters are available. Because they are light, you can use them for either temporary or permanent situations. Permanent floor supports or temporary tripod-style stands are also available. You can use roller curve units for corners.

Ancillary Components

Working Platform

The Working Platform is compact, stable, and safe with guardrails and a ladder.

Features:

Dimensions: 1900x1900x1800-2000mm (customizable)

Made of 304S.S.